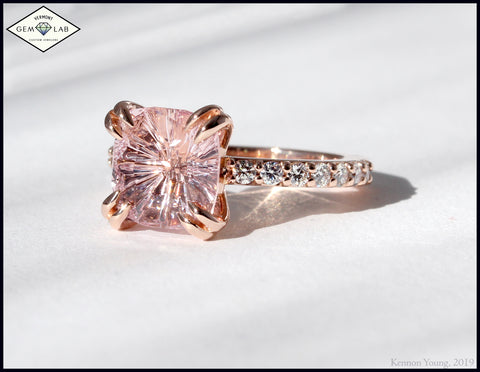

Our Jewelry Design Process

Please Click Here to Download our Custom Jewelry Design Manual

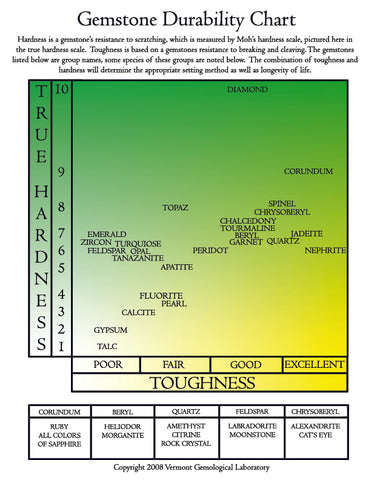

Step One: DiscoveryThe first meeting is one of education, exploration, and information. We will indentify and grade any family stones that might be used and which metals and setting they allow. We will talk about and see examples or precious metals, diamonds, gemstones, methods of manufacturing, how the ring will be worn, and more.

Step Two: SourcingYour ASA master Gemologist Appraiser will source diamonds, gemstones, or pre-manufactured component parts to see and discuss. Typically, stones and components are sourced for viewing and they can be returned. This is to ensure that the components used are exactly what you’re looking for. There could be several rounds of sourcing meetings and several rounds of viewing component parts.

A custom design is built around the stones and the size of the person (e.g. finger size, or chain length). These non-variables are programmed into a Computer Aided Design (CAD) program. The jewelry item is manufactured in a digital format. This method of manufacturing allows for perfect geometry and little ambiguity of the future design. CAD renders are created, which show a virtual rendition of the final piece, and 3D prints are created, which will show a to-scale model. At this stage, changes and design details can be discussed and altered with little difficulty, before a final design is created.

Step Four: Physical ManufacturingIn this stage, an approved CAD file is emailed to a casting house where it’s 3D printed and cast in your metal of choice. The casting is shipped to the Gem Lab to have the casting sanded, filed, polished, and the stones set.